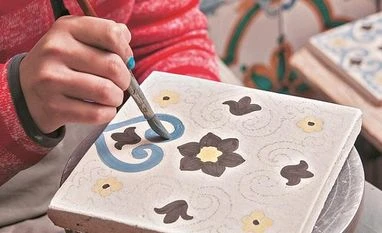

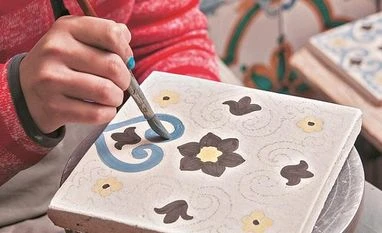

New registration norms by Saudi add to Morbi tile cluster's woes

The Saudi Arabian government has changed technical requirements for suppliers of ceramic tiles, forcing the units in Morbi to apply for certification for valid exports

)

Explore Business Standard

Associate Sponsors

Co-sponsor

The Saudi Arabian government has changed technical requirements for suppliers of ceramic tiles, forcing the units in Morbi to apply for certification for valid exports

)

Already subscribed? Log in

Subscribe to read the full story →

3 Months

₹300/Month

1 Year

₹225/Month

2 Years

₹162/Month

Renews automatically, cancel anytime

Over 30 premium stories daily, handpicked by our editors

News, Games, Cooking, Audio, Wirecutter & The Athletic

Digital replica of our daily newspaper — with options to read, save, and share

Insights on markets, finance, politics, tech, and more delivered to your inbox

In-depth market analysis & insights with access to The Smart Investor

Repository of articles and publications dating back to 1997

Uninterrupted reading experience with no advertisements

Access Business Standard across devices — mobile, tablet, or PC, via web or app

First Published: Oct 12 2019 | 1:46 PM IST