The domestic secondary steel industry contributes nearly 55 per cent to the total production of the alloy in the country. These players produce steel through the electrical route unlike the primary steel producers who use blast furnaces to make the alloy. The letter to the PMO was sent by the All India Induction Furnace Association on September 25, 2020.

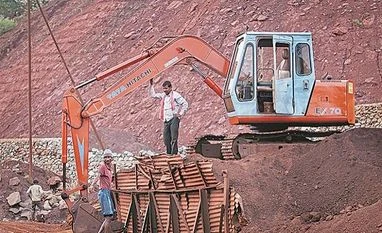

There are more than 2,000 secondary steel units across the country, which include sponge iron producers, induction furnace and rolling mills.

“Iron ore and pellet prices have jumped nearly 40 per cent in the last six months starting March due to a supply crunch. This has impacted the margins of secondary steel producers who were already dealing with weak business climate due to Covid-19,” Kaushik Agarwal, chief financial officer at Brahmaputra Metallics Limited told Business Standard.

Pellets are small balls of iron ore used in the production of steel. The raw material forms 60 per cent of the cost of production of steel and hence a spike in prices of the commodity hurts margins.

“In the last six weeks, prices of finished steel have declined by 8-10 percent. With raw material prices remaining stiff, secondary producers are facing margins contraction of about 10-11 percent (in the period under review),” said Agarwal.

Brahmaputra Metallics Limited runs a coal-based 105,000 tonne sponge iron unit in Jharkhand.

The recently concluded iron ore mining auction in Odisha has also added to the woes of the secondary players as nearly 50 per cent of the mines auctioned have gone to large steel players for captive usage and the remainder, which have gone to merchant miners, are yet to start production. This has brought about a shortage of the material in the domestic market.

“As if domestic shortage was not enough (due to auctioning), NMDC is also exporting the ore for better realisations. On a monthly basis, nearly 10-11 lakh tonne ore is moving out of the country which is double from last year,” said another sponge iron producer on condition of anonymity.

In FY20, India’s iron ore exports rose to 37.69 million tonne from 16.15 million tonne in 2018-19, a jump of nearly 133 per cent, said the letter to the PMO.

Owing to the strong demand from China, India exported nearly 30.86 million tonne iron ore, 82 per cent of total exports to China alone,it said.

Meanwhile, Odisha Mining Corporation (OMC) is bringing some relief to the secondary players in terms of supply, but prices of the material remain elevated. India’s iron ore production during Apr-Jul period stood at 47 million tonne, down 50 percent over same period last year.

“It is a tough business environment due to increase ore prices. We are getting our supply from OMC as of now but at a very high price,” said Debabrata Behera, managing director of Odisha-based Kashvi Power & Steel Pvt Ltd.

)