Behind India's ventilator crisis: Lack of trained staff and idle units

Oxygen makers flag concern over shortage of liquid oxygen

)

premium

The medical oxygen manufacturing industry is facing a growing challenge of liquid oxygen production

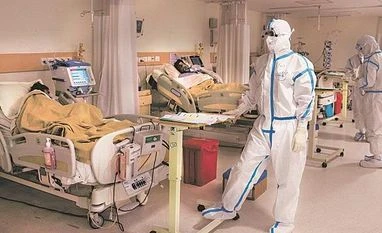

The second wave of the pandemic has not only crippled medical infrastructure in terms of hospital beds, but has also led to bottlenecks in invasive ventilators and medical oxygen capacities and supplies.

On the one hand, the invasive ventilator industry is finding idle stock lying at certain hospitals for want of trained manpower to operate them as against other hospitals with critical cases that lack such equipment. On the other, the medical oxygen manufacturing industry is facing a growing challenge of liquid oxygen production. As a result, invasive ventilator manufacturers have asked state and central governments to redistribute idle stocks to hospitals that are in need and have trained manpower to operate them.

According to V Alva, founder of Skanray Technologies, a leading invasive ventilator manufacturer, the challenge is not so much shortage of equipment but of trained intensive care unit (ICU) specialists, known as intensivists and respiratory technicians. “There is an acute shortage here. We have already supplied over 30,000 ventilators to the government and another 5,000 to private facilities and can supply more as required. But the country currently has only about 10,000 intensivists as against over 50,000 ventilators. There is also a non-uniform distribution of invasive ventilators,” said Alva.

For another such player, Max Ventilators, demand for invasive ventilators has shot up overnight, forcing it to work on ramping up its production from 15-20 ventilators per day to 35 daily, which it plans to achieve in a week’s time.

“One of the challenges is procuring raw materials... We are working with our 350-odd vendors for matching supply of components with the speed of ventilator production. We are assisting hospitals and medical centres in improving their lower 1:10 ratio of ICU beds to ventilators. Given that such ventilators require trained manpower, at many places centres are being advised to treat patients in a non-invasive mode,” said Ashok Patel, managing director of Max Ventilators.

On the one hand, the invasive ventilator industry is finding idle stock lying at certain hospitals for want of trained manpower to operate them as against other hospitals with critical cases that lack such equipment. On the other, the medical oxygen manufacturing industry is facing a growing challenge of liquid oxygen production. As a result, invasive ventilator manufacturers have asked state and central governments to redistribute idle stocks to hospitals that are in need and have trained manpower to operate them.

According to V Alva, founder of Skanray Technologies, a leading invasive ventilator manufacturer, the challenge is not so much shortage of equipment but of trained intensive care unit (ICU) specialists, known as intensivists and respiratory technicians. “There is an acute shortage here. We have already supplied over 30,000 ventilators to the government and another 5,000 to private facilities and can supply more as required. But the country currently has only about 10,000 intensivists as against over 50,000 ventilators. There is also a non-uniform distribution of invasive ventilators,” said Alva.

For another such player, Max Ventilators, demand for invasive ventilators has shot up overnight, forcing it to work on ramping up its production from 15-20 ventilators per day to 35 daily, which it plans to achieve in a week’s time.

“One of the challenges is procuring raw materials... We are working with our 350-odd vendors for matching supply of components with the speed of ventilator production. We are assisting hospitals and medical centres in improving their lower 1:10 ratio of ICU beds to ventilators. Given that such ventilators require trained manpower, at many places centres are being advised to treat patients in a non-invasive mode,” said Ashok Patel, managing director of Max Ventilators.